Making a mask REAL fast

By Sam Chiverton and Santiago Lau Vasquez

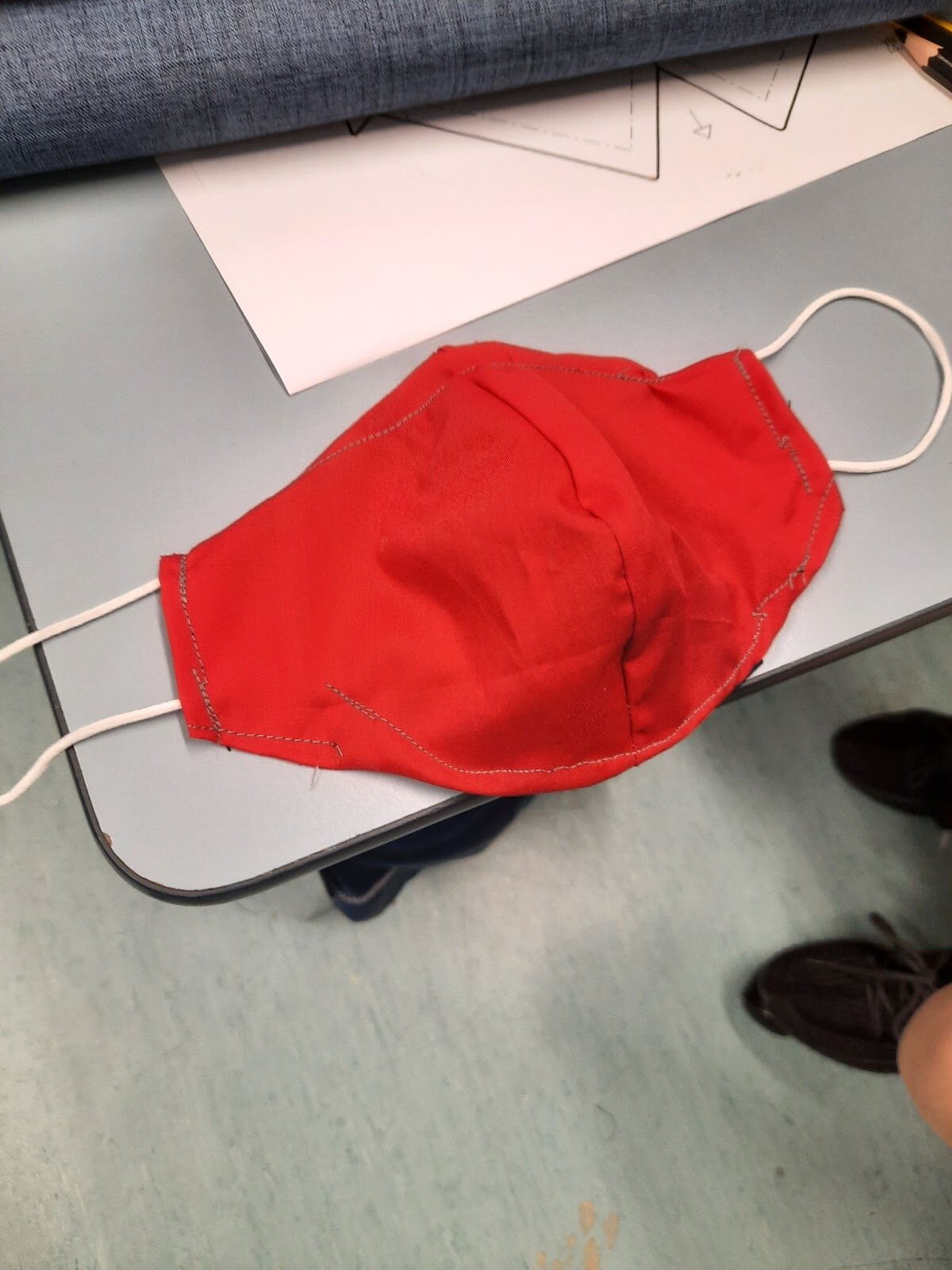

The finished product.

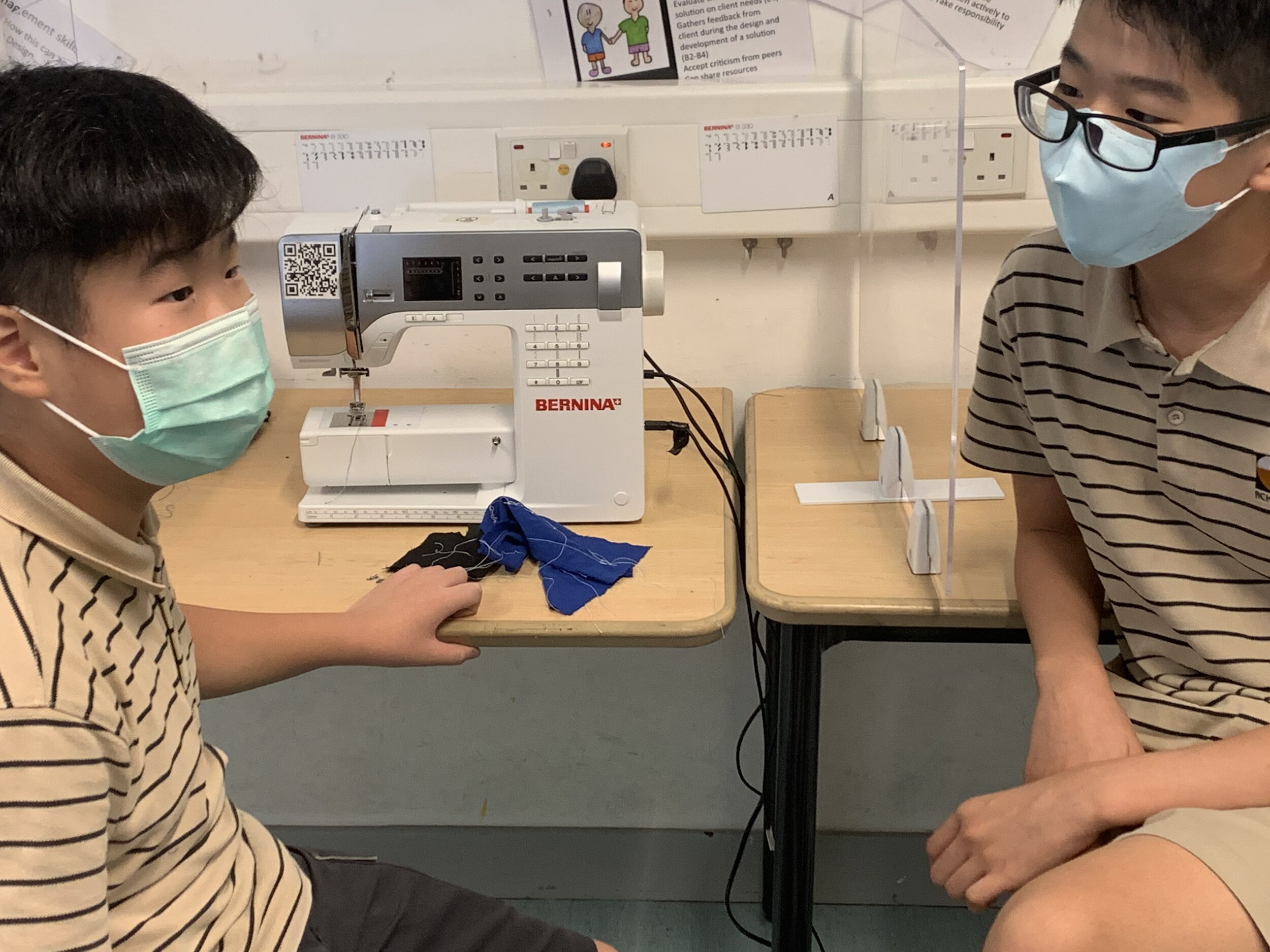

Sewing can be somewhat therapeutic for some of us.

It can also raise awareness of fabric waste. As one group of REAL students discovered when they created re-usable masks made from recycled fabrics.

The Tides of T-shirt trends REAL group partnered up with the Pandemic REAL class to work on this project during the REAL Deep Dive Days of May 31 and June 1.

Their aim was to create a reusable mask using waste fabrics such as T-shirts that had a similar function to a standard surgical mask in the hope of raising awareness about fabric and textile waste, while at the same time, trying to use a more sustainable option to disposable masks.

Every year 100,000 tonnes of fabrics are put to waste in Hong Kong alone. Initially, this was what they were going to inquire into. Where do wasted fabrics end up? What happens to unused materials in the garment industry? These were the types of questions they were going to address. For the Deep Dive Days though the focus narrowed to the creation of reusable and protective masks made from recycled textiles.

It may seem simple - cutting up some cloth and adding strings - but the reality was much more complicated.

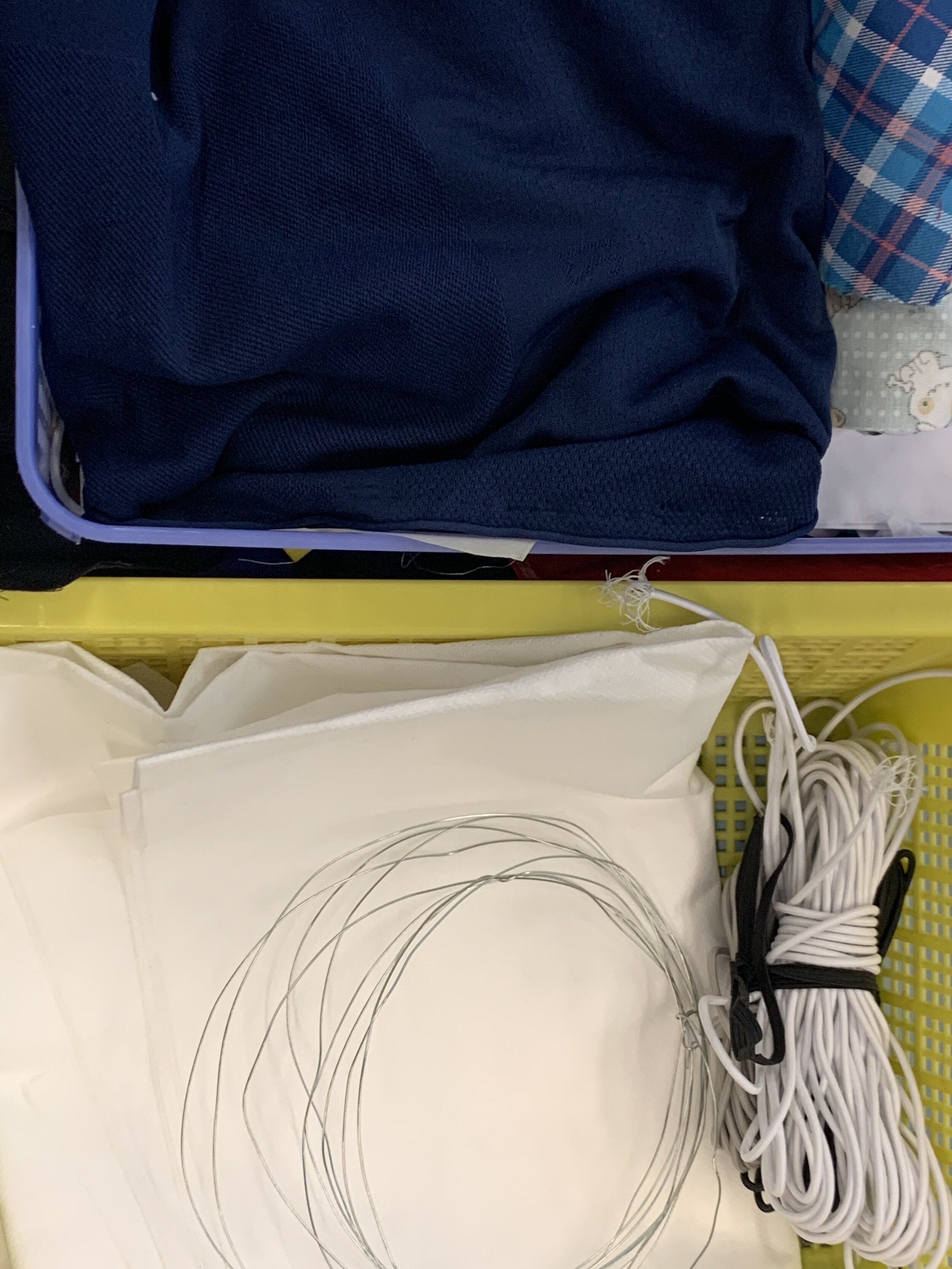

The way they planned to reach their goal was firstly to choose their materials to fit their needs and wants. Then they would choose a size of a mask that the students feel would fit best on themselves. Once this was done, they would take a paper template of the desired size and cut their fabrics around the template. Finally, they would sew everything together using a sewing machine.

For their masks to have similar functions and protection to standard disposable surgical masks, then their masks had to pass a test that would determine whether or not they were protective. They used a range of cottons, polyester cottons and nylon to create a three layered protective mask.

In terms of quality control testing, the groups used water droplets to see if they penetrated the protective layers. Just like harmful virus droplets, the water droplets should not be able to pass through the mask. If it did pass through, those masks could not be used, for the safety of others.

The students did not make the filters themselves. They did however have the option to insert a bought mask filter into a pocket inside the masks they made.

By the end of June 1 the students had managed to create the masks they intended. The textiles seemed smooth and comfortable to wear. The ear loops were made of white elastic for easy and flexible fitting. The masks were colourful and each unique in their own way.